What You Need to Know About the Evolving Footwear Industry

The footwear industry is undergoing a significant transformation, driven by the increasing importance of safety standards. At the forefront of this change is the American Society for Testing and Materials (ASTM), a leading organization that sets guidelines for manufacturers to ensure consumer safety. The new ASTM standards for footwear specify that it should meet certain criteria, and understanding these requirements is crucial for footwear manufacturers. Staying updated with the latest standards is vital to prevent injuries, reduce liability, and maintain a positive brand reputation. In fact, the new ASTM standards for footwear specify that it should adhere to rigorous testing and certification processes to guarantee the quality and performance of footwear products. By staying informed about the latest developments in ASTM standards, footwear manufacturers can ensure compliance, improve product safety, and ultimately, enhance their brand reputation.

How to Ensure Compliance with the New ASTM Standards for Footwear

The new ASTM standards for footwear specify that it should meet certain criteria, and understanding these requirements is crucial for footwear manufacturers. To ensure compliance, manufacturers must familiarize themselves with the key changes and updates in the new standards. One of the significant updates is the emphasis on rigorous testing and certification processes to guarantee the quality and performance of footwear products. Footwear manufacturers must implement these changes in their production processes by adopting new testing protocols, updating their quality control measures, and ensuring that their products meet the specified standards. Additionally, manufacturers should establish a system for tracking and documenting their compliance with the new standards, including maintaining records of testing and certification. By taking these steps, footwear manufacturers can ensure that their products meet the latest ASTM standards, reducing the risk of non-compliance and improving overall product safety.

The Impact of ASTM Standards on Footwear Performance and Quality

The correlation between ASTM standards and footwear performance is undeniable. Compliance with these standards can significantly improve the overall quality of footwear products, leading to enhanced customer satisfaction and loyalty. The new ASTM standards for footwear specify that it should meet certain criteria, such as rigorous testing and certification processes, to guarantee the quality and performance of footwear products. By adhering to these standards, footwear manufacturers can ensure that their products meet the highest levels of quality, durability, and safety. This, in turn, can lead to increased customer trust and loyalty, as well as improved brand reputation. Furthermore, compliance with ASTM standards can also reduce the risk of product recalls, lawsuits, and other legal issues, ultimately saving manufacturers time and resources. By prioritizing compliance with ASTM standards, footwear manufacturers can create high-quality products that meet the evolving needs of consumers, while also staying ahead of the competition.

Deciphering the New ASTM Standards: A Breakdown of Key Specifications

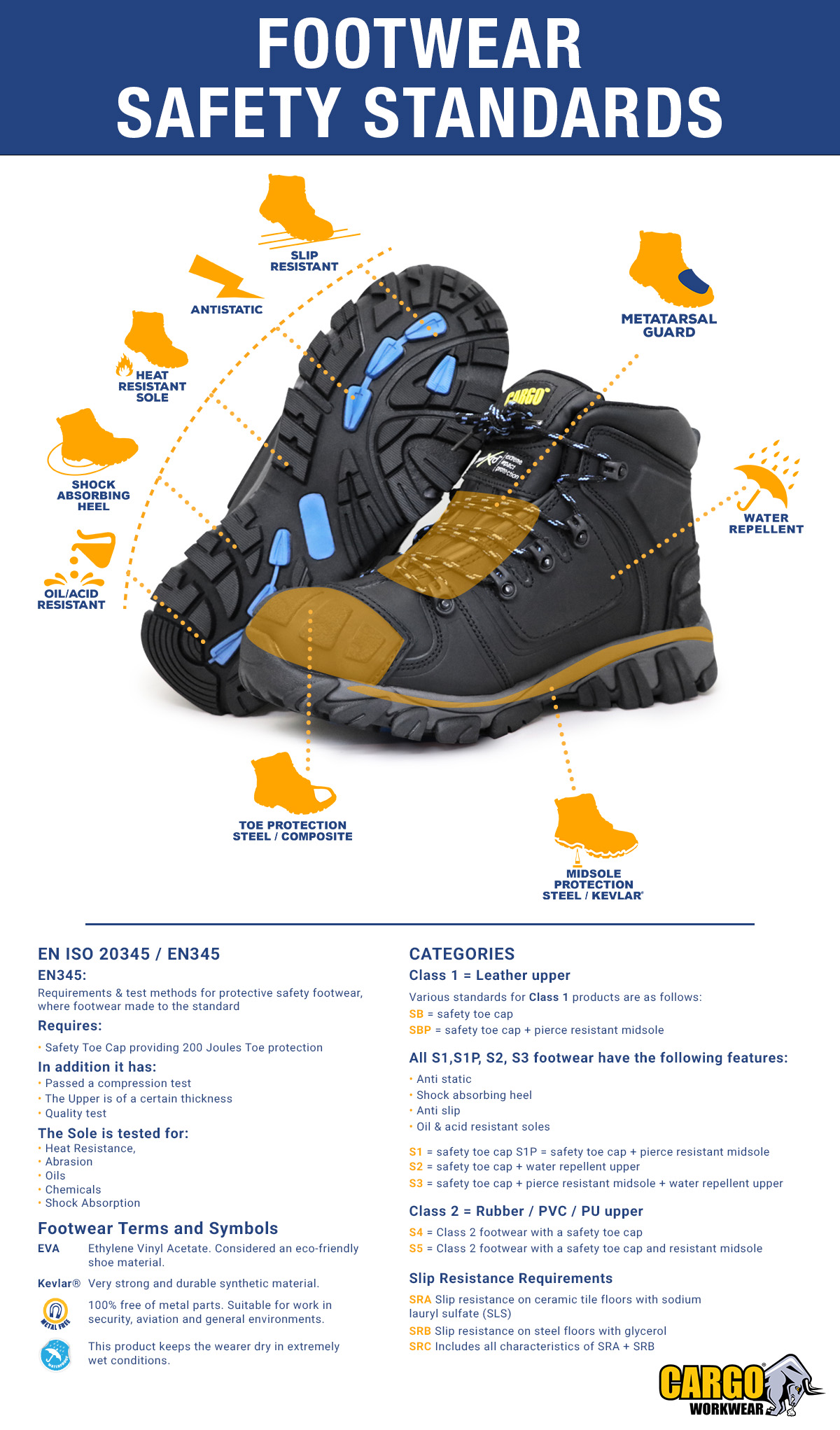

The new ASTM standards for footwear specify that it should meet certain technical requirements, which are crucial for ensuring the quality and safety of footwear products. One of the key specifications is the use of high-quality materials that can withstand various environmental conditions, such as water, heat, and cold. For instance, the standards require that footwear materials should be able to resist water penetration and absorption, ensuring that the product remains durable and safe in wet conditions. Additionally, the standards specify that footwear products should have a certain level of slip resistance, which is critical for preventing accidents and injuries. Footwear manufacturers must also ensure that their products meet the standards for labeling and marking, which includes providing clear and accurate information about the product’s materials, size, and care instructions. By understanding these technical requirements, footwear manufacturers can ensure that their products meet the highest standards of quality and safety, ultimately benefiting consumers and enhancing their brand reputation.

The Role of Testing and Certification in Ensuring ASTM Compliance

Testing and certification play a crucial role in verifying compliance with the new ASTM standards for footwear. The standards specify that it should undergo rigorous testing and certification processes to ensure that footwear products meet the required safety and quality standards. Footwear manufacturers can choose from various testing and certification options, including in-house testing, third-party testing, and certification from recognized organizations such as UL (Underwriters Laboratories) or Intertek. These testing and certification processes involve evaluating footwear products against specific criteria, such as performance, safety, and durability. By undergoing these processes, footwear manufacturers can ensure that their products meet the highest standards of quality and safety, ultimately reducing the risk of product recalls, lawsuits, and other legal issues. Moreover, testing and certification can also help footwear manufacturers to identify areas for improvement, optimize their production processes, and enhance their brand reputation.

What Footwear Manufacturers Need to Know About ASTM Standards and Regulations

Footwear manufacturers must stay informed about the regulatory landscape surrounding ASTM standards to ensure compliance and avoid legal implications. The new ASTM standards for footwear specify that it should meet certain safety and quality requirements, and non-compliance can result in product recalls, fines, and damage to brand reputation. To stay ahead of regulatory changes, footwear manufacturers can subscribe to ASTM’s standards updates, attend industry conferences, and participate in trade associations. Additionally, they can work with regulatory experts and legal counsel to ensure that their products meet the required standards. It is also essential for footwear manufacturers to maintain accurate records of testing, certification, and compliance, as these can be used as evidence in case of legal disputes. By staying informed and proactive, footwear manufacturers can minimize the risk of non-compliance and ensure that their products meet the highest standards of safety and quality.

The Benefits of Adopting the New ASTM Standards for Footwear

Adopting the new ASTM standards for footwear can bring numerous benefits to manufacturers, including improved product safety, enhanced brand reputation, and increased customer trust. By complying with these standards, footwear manufacturers can ensure that their products meet the highest safety and quality requirements, reducing the risk of product recalls and legal liabilities. The new ASTM standards for footwear specify that it should undergo rigorous testing and certification processes, which can help manufacturers identify and address potential safety issues early on. Additionally, compliance with these standards can also lead to cost savings, as manufacturers can avoid costly re-designs and re-tests. Furthermore, adopting the new ASTM standards can also help footwear manufacturers to stay competitive in the market, as consumers increasingly demand high-quality and safe products. By prioritizing safety and quality, footwear manufacturers can build trust with their customers, enhance their brand reputation, and ultimately drive business growth.

Staying Ahead of the Curve: The Future of Footwear Safety and ASTM Standards

As the footwear industry continues to evolve, it is essential for manufacturers to prioritize innovation and continuous improvement in their products. The new ASTM standards for footwear specify that it should meet certain safety and quality requirements, and manufacturers must stay ahead of the curve to ensure compliance. Looking to the future, footwear manufacturers can expect ASTM standards to continue to evolve, with a focus on emerging technologies and materials. For example, the use of sustainable materials and 3D printing technology is becoming increasingly popular, and ASTM standards will need to adapt to these changes. By staying informed about the latest developments and updates to ASTM standards, footwear manufacturers can ensure that their products remain safe, high-quality, and competitive in the market. Additionally, manufacturers can also invest in research and development to identify new opportunities for innovation and improvement. By doing so, they can not only stay compliant with ASTM standards but also drive growth and success in the industry.