Why Slip and Oil Resistance Matters

In various industries, such as manufacturing, construction, and food service, slips, trips, and falls are a major concern. According to the Occupational Safety and Health Administration (OSHA), slips, trips, and falls account for a significant percentage of workplace accidents, resulting in injuries, fatalities, and substantial financial losses. One crucial aspect of preventing these accidents is wearing the right footwear, specifically slip resistant oil resistant shoes. These shoes are designed to provide traction on slippery surfaces, reducing the risk of accidents and ensuring a safe working environment. In industries where oil and other hazardous substances are present, oil resistant materials are essential to prevent the shoes from deteriorating and losing their slip-resistant properties. By wearing slip resistant oil resistant shoes, workers can significantly reduce the risk of accidents and injuries, ultimately contributing to a safer and more productive workplace.

How to Choose the Perfect Slip Resistant Oil Resistant Shoes

When it comes to selecting the right slip resistant oil resistant shoes, there are several factors to consider. The type of outsole, materials, and certifications are all crucial in ensuring that the shoes provide the necessary traction and protection. For instance, shoes with a lug sole pattern are ideal for oily surfaces, while those with a flat sole pattern are better suited for dry surfaces. Additionally, shoes made from high-quality materials such as rubber and polyurethane are more durable and resistant to oil and chemicals. Certifications such as ASTM and EN ISO 20345 also guarantee that the shoes meet certain standards for slip resistance and safety. Furthermore, considering the specific industry and work environment is essential in choosing the right slip resistant oil resistant shoes. For example, shoes for the food service industry may require additional features such as slip resistance on wet and oily surfaces, while shoes for the construction industry may need to be more durable and resistant to heavy wear and tear. By taking these factors into account, workers can ensure that they are wearing the right slip resistant oil resistant shoes for their job, reducing the risk of accidents and injuries.

Top Picks: Dr. Martens and Timberland Slip Resistant Oil Resistant Shoes

When it comes to slip resistant oil resistant shoes, two brands stand out for their quality and performance: Dr. Martens and Timberland. Both brands offer a range of slip resistant oil resistant shoes that cater to different industries and work environments. Dr. Martens’ Ironbridge collection, for instance, features shoes with a rugged outsole and a breathable membrane, making them ideal for construction and manufacturing workers. The shoes also meet the ASTM F2413-11 standard for slip resistance. On the other hand, Timberland’s PRO collection offers shoes with a unique outsole design that provides excellent traction on oily surfaces. The shoes are also made with high-quality materials that are resistant to oil and chemicals. One of the standout features of Timberland’s slip resistant oil resistant shoes is their anti-fatigue technology, which reduces foot fatigue and discomfort. While both brands offer high-quality slip resistant oil resistant shoes, Dr. Martens’ shoes are generally more affordable, with prices starting at around $100. Timberland’s shoes, on the other hand, are priced slightly higher, with prices starting at around $150. Ultimately, the choice between Dr. Martens and Timberland slip resistant oil resistant shoes depends on the specific needs and preferences of the worker.

The Science Behind Slip Resistance: Understanding Coefficient of Friction

When it comes to slip resistant oil resistant shoes, understanding the science behind slip resistance is crucial. At the heart of slip resistance is the concept of coefficient of friction, which measures the frictional force between two surfaces. In the context of slip resistant oil resistant shoes, the coefficient of friction refers to the ability of the shoe’s outsole to grip the floor and resist slipping. A higher coefficient of friction indicates better slip resistance. There are several testing methods used to measure the coefficient of friction, including the ASTM F489 test, which involves measuring the force required to slide a shoe across a surface. The EN ISO 20345 standard also provides guidelines for testing the slip resistance of slip resistant oil resistant shoes. In addition to the testing methods, there are also different types of slip resistance, including static coefficient of friction, which measures the frictional force when the shoe is stationary, and dynamic coefficient of friction, which measures the frictional force when the shoe is in motion. By understanding the coefficient of friction and the different testing methods and standards, workers can make informed decisions when selecting slip resistant oil resistant shoes that meet their specific needs and work environments.

Oil Resistant Materials: What You Need to Know

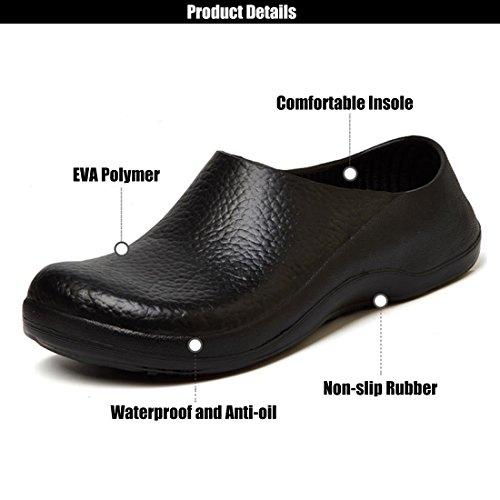

When it comes to slip resistant oil resistant shoes, the type of material used is crucial in determining their performance. Oil resistant materials are designed to withstand the corrosive effects of oils and chemicals, ensuring that the shoes remain effective in slippery environments. There are several types of oil resistant materials used in slip resistant oil resistant shoes, each with its own advantages and disadvantages. Rubber, for instance, is a popular choice due to its excellent grip and durability. However, it can be heavy and may not be suitable for certain industries. Polyurethane, on the other hand, is a lightweight and flexible material that provides excellent oil resistance. However, it may not be as durable as rubber. Nitrile, a synthetic rubber, is another popular choice due to its excellent oil resistance and durability. However, it can be more expensive than other materials. Other materials used in slip resistant oil resistant shoes include PVC, TPU, and EVA. When selecting slip resistant oil resistant shoes, it’s essential to consider the type of material used and its suitability for the specific work environment. By understanding the different oil resistant materials and their properties, workers can make informed decisions when choosing the right slip resistant oil resistant shoes for their needs.

Slip Resistant Oil Resistant Shoes for Specific Industries

Different industries have unique requirements when it comes to slip resistant oil resistant shoes. For instance, in the food processing industry, shoes need to be resistant to oils and fats, as well as easy to clean and sanitize. In construction, shoes need to be durable and able to withstand rough terrain, while also providing protection from hazardous materials. In manufacturing, shoes need to be able to withstand the wear and tear of production lines, while also providing protection from oils and chemicals. When selecting slip resistant oil resistant shoes for a specific industry, it’s essential to consider the unique challenges and hazards of that industry. For example, in the food service industry, shoes with a slip-resistant outsole and a breathable upper are ideal for preventing slips and falls in kitchens and restaurants. In the construction industry, shoes with a rugged outsole and a durable upper are ideal for withstanding rough terrain and hazardous materials. By understanding the specific requirements of each industry, workers can choose the right slip resistant oil resistant shoes to ensure their safety and protection. Some popular slip resistant oil resistant shoes for specific industries include the Dr. Martens Ironbridge for construction, the Timberland PRO Boondock for manufacturing, and the New Balance 626v2 for food processing. By selecting the right slip resistant oil resistant shoes for their industry, workers can reduce the risk of slips, trips, and falls, and ensure a safe and healthy work environment.

Breaking In and Maintaining Your Slip Resistant Oil Resistant Shoes

Once you’ve invested in a pair of slip resistant oil resistant shoes, it’s essential to break them in properly to ensure optimal performance. Breaking in new shoes can take some time, but it’s crucial to prevent discomfort and blisters. Start by wearing the shoes for short periods, gradually increasing the time over the course of a few days. This will allow the shoes to mold to your feet and reduce the risk of discomfort. Additionally, consider using shoe stretchers or conditioners to help soften the materials and reduce break-in time. To maintain the performance of your slip resistant oil resistant shoes, regular cleaning and storage are essential. Use a mild soap and water to clean the shoes, avoiding harsh chemicals that can damage the materials. Allow the shoes to air dry, rather than using heat to speed up the process. When storing the shoes, keep them in a cool, dry place away from direct sunlight. This will help prevent the materials from degrading over time. By following these simple tips, workers can ensure their slip resistant oil resistant shoes remain effective and comfortable, providing protection and support throughout their shift. Regular maintenance can also extend the lifespan of the shoes, reducing the need for frequent replacements and saving workers money in the long run. By prioritizing the care and maintenance of their slip resistant oil resistant shoes, workers can ensure a safe and healthy work environment.

Conclusion: Prioritizing Safety with the Right Footwear

In conclusion, slip resistant oil resistant shoes play a critical role in ensuring workplace safety across various industries. By understanding the importance of slip and oil resistance, selecting the right shoes, and maintaining their performance, workers can significantly reduce the risk of slips, trips, and falls. It’s essential for employers and workers to prioritize safety and invest in high-quality slip resistant oil resistant shoes that meet the specific requirements of their industry. By doing so, they can create a safe and healthy work environment, reduce the risk of injuries and accidents, and improve overall productivity. Remember, safety should always be the top priority, and the right footwear can make all the difference. By choosing the right slip resistant oil resistant shoes, workers can take a crucial step towards a safer and more secure work environment.