Why Oil and Water Resistance Matters

In industries where oil and water are present, the risk of slips, trips, and falls is ever-present. According to the Occupational Safety and Health Administration (OSHA), slips, trips, and falls are a leading cause of workplace accidents, resulting in thousands of injuries and fatalities every year. The consequences of these accidents can be severe, ranging from minor sprains and strains to serious head trauma, broken bones, and even death. In addition to the human toll, workplace accidents can also have a significant impact on businesses, resulting in lost productivity, increased workers’ compensation claims, and damage to equipment and property.

Oil and water slip-resistant shoes are a crucial component of a comprehensive safety strategy in these industries. By providing traction on slippery surfaces, these shoes can help prevent accidents and injuries, reducing the risk of slips, trips, and falls. In fact, a study by the National Institute for Occupational Safety and Health (NIOSH) found that wearing slip-resistant shoes can reduce the risk of falls by up to 50%. With the right footwear, workers can feel more confident and secure on the job, allowing them to focus on their tasks without worrying about their safety.

In industries such as manufacturing, construction, and food processing, oil and water are often present on the floor, creating a hazardous environment for workers. In these situations, oil water slip-resistant shoes are essential for preventing accidents and injuries. By choosing the right shoes for the job, workers can reduce their risk of slipping and falling, and employers can create a safer, more productive work environment.

How to Choose the Right Slip-Resistant Shoes for Your Job

Selecting the right oil water slip-resistant shoes for your job can be a daunting task, especially with the numerous options available in the market. However, by considering a few key factors, you can make an informed decision that meets your specific needs and ensures your safety on the job.

First and foremost, it’s essential to consider the type of occupation you’re in. Different industries present unique challenges, and the right shoes can make all the difference. For instance, if you work in a manufacturing setting where oil is present, you’ll need shoes with a high level of oil resistance. On the other hand, if you work in a food processing plant where water is present, you’ll need shoes with excellent water resistance.

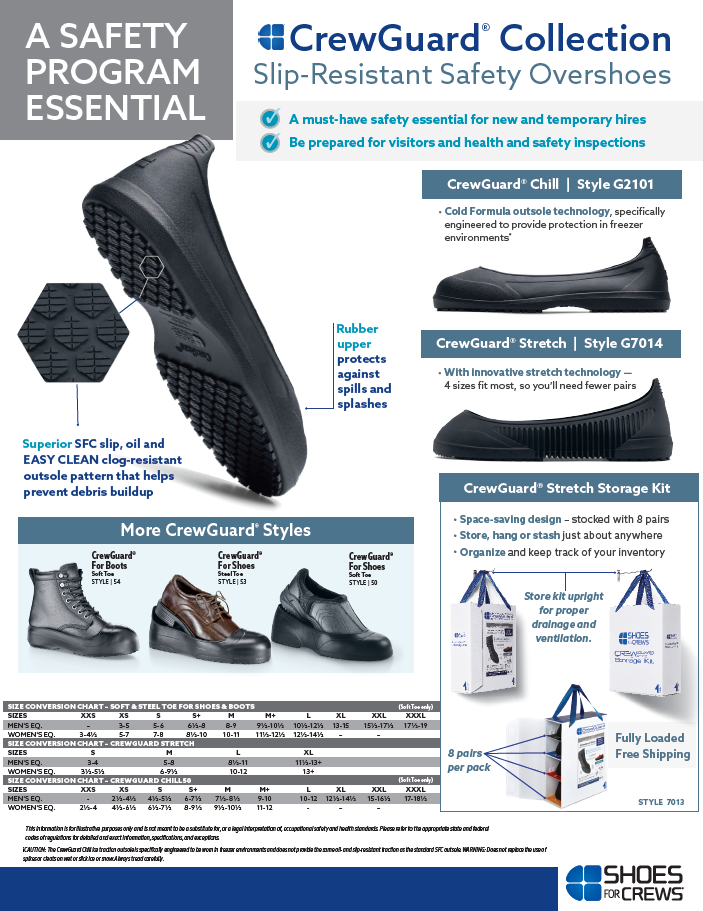

Next, consider the sole material and tread pattern of the shoes. Look for shoes with a rubber or polyurethane sole, as these materials provide excellent traction on slippery surfaces. The tread pattern is also crucial, as it determines the level of grip on different surfaces. For example, shoes with a herringbone or circular tread pattern are ideal for oily surfaces, while shoes with a deep lug tread pattern are better suited for wet surfaces.

Certification standards are also a critical factor to consider. Look for shoes that meet or exceed industry standards such as ASTM or EN. These certifications ensure that the shoes have been tested and proven to provide a certain level of slip resistance. Additionally, consider the level of certification, as some shoes may be certified for specific industries or hazards.

Finally, consider the comfort and durability of the shoes. You’ll be wearing these shoes for extended periods, so it’s essential to choose shoes that are comfortable and can withstand the demands of your job. Look for shoes with breathable materials, cushioning, and a comfortable fit.

By considering these factors, you can choose the right oil water slip-resistant shoes for your job, ensuring your safety and comfort on the job. Remember, the right shoes can make all the difference in preventing accidents and injuries, so take the time to make an informed decision.

Top-Rated Oil and Water Slip-Resistant Shoes for Work

When it comes to selecting the best oil water slip-resistant shoes for your job, there are numerous options available in the market. To help you make an informed decision, we’ve reviewed and compared top-rated oil water slip-resistant shoes from leading brands like Dr. Martens, Timberland, and Thorogood.

Dr. Martens Ironbridge Oil-Resistant Shoes: These shoes feature a rugged outsole with a unique tread pattern that provides excellent traction on oily surfaces. With a breathable membrane and comfortable cushioning, these shoes are ideal for workers in manufacturing and construction industries.

Timberland PRO Boondock Oil-Resistant Shoes: Designed for workers in the oil and gas industry, these shoes feature a rugged outsole with a deep lug tread pattern that provides excellent grip on slippery surfaces. With a waterproof membrane and comfortable ankle support, these shoes are perfect for workers who need protection and comfort on the job.

Thorogood American Made Oil-Resistant Shoes: These shoes feature a rugged outsole with a herringbone tread pattern that provides excellent traction on oily surfaces. With a breathable membrane and comfortable cushioning, these shoes are ideal for workers in food processing and healthcare industries.

All three of these top-rated oil water slip-resistant shoes have received excellent customer reviews, with workers praising their comfort, durability, and slip-resistance. When choosing the right shoes for your job, consider the specific hazards and challenges of your industry, and select shoes that meet or exceed industry standards for slip-resistance.

By investing in high-quality oil water slip-resistant shoes, you can reduce the risk of accidents and injuries on the job, and create a safer, more productive work environment. Remember, the right shoes can make all the difference in preventing slips, trips, and falls, so take the time to choose the best oil water slip-resistant shoes for your job.

The Science Behind Slip-Resistant Technology

Slip-resistant shoes are designed to provide traction on oily and wet surfaces, reducing the risk of slips, trips, and falls. But what makes these shoes so effective? The answer lies in the technology behind slip-resistant shoes, including the role of materials, tread patterns, and surface treatments.

Materials play a crucial role in slip-resistant shoes. Rubber and polyurethane are commonly used materials that provide excellent traction on oily and wet surfaces. These materials are often combined with other compounds to enhance their slip-resistance. For example, some shoes feature a unique blend of rubber and silica that provides exceptional grip on slippery surfaces.

Tread patterns are another critical factor in slip-resistant shoes. The tread pattern determines the level of grip on different surfaces. For example, shoes with a herringbone tread pattern are ideal for oily surfaces, while shoes with a deep lug tread pattern are better suited for wet surfaces. The tread pattern also affects the self-cleaning ability of the shoe, with some patterns allowing for easier removal of debris and contaminants.

Surface treatments are also used to enhance the slip-resistance of shoes. For example, some shoes feature a special coating that increases the friction between the shoe and the surface. This coating can be applied to the entire sole or specific areas, such as the heel and toe.

In addition to materials, tread patterns, and surface treatments, slip-resistant shoes often feature other technologies that enhance their performance. For example, some shoes feature a breathable membrane that allows moisture to escape, reducing the risk of slipping on wet surfaces. Others feature a cushioning system that absorbs shock and provides additional traction.

Oil water slip-resistant shoes are designed to provide traction on a variety of surfaces, from oily manufacturing floors to wet food processing facilities. By understanding the technology behind these shoes, workers can make informed decisions about the best footwear for their job, and employers can ensure a safer, more productive work environment.

By investing in high-quality oil water slip-resistant shoes, workers can reduce the risk of accidents and injuries, and create a safer, more productive work environment. Remember, the right shoes can make all the difference in preventing slips, trips, and falls, so take the time to understand the science behind slip-resistant technology.

Real-Life Scenarios: When Slip-Resistant Shoes Saved the Day

In hazardous work environments, the right footwear can mean the difference between safety and disaster. Oil water slip-resistant shoes have saved countless workers from accidents and injuries, and here are just a few examples:

In a manufacturing plant, a worker was tasked with cleaning up a spill on the factory floor. The floor was slick with oil, and the worker was at risk of slipping and falling. But thanks to their oil water slip-resistant shoes, they were able to navigate the hazardous surface with ease, avoiding a potentially serious accident.

In a food processing facility, a worker was moving heavy crates of produce across a wet floor. The floor was slippery with water and food residue, but the worker’s oil water slip-resistant shoes provided the necessary traction to prevent a slip and fall.

In a construction site, a worker was working on a scaffolding high above the ground. The scaffolding was slippery with oil and water, but the worker’s oil water slip-resistant shoes gave them the confidence to move around safely, even in the most precarious situations.

These real-life scenarios demonstrate the importance of oil water slip-resistant shoes in hazardous work environments. By wearing the right footwear, workers can reduce the risk of accidents and injuries, and create a safer, more productive work environment.

In each of these scenarios, the workers were able to avoid accidents and injuries thanks to their oil water slip-resistant shoes. These shoes provided the necessary traction and grip to navigate hazardous surfaces, and gave workers the confidence to perform their jobs safely and effectively.

By investing in high-quality oil water slip-resistant shoes, employers can demonstrate their commitment to worker safety and well-being. And by wearing these shoes, workers can take control of their own safety and reduce the risk of accidents and injuries.

Slip-Resistant Shoes for Specific Industries: A Guide

Oil water slip-resistant shoes are essential in various industries where hazardous surfaces are a common occurrence. Different industries have unique challenges and requirements, and it’s crucial to choose the right slip-resistant shoes for the job. Here’s a guide to slip-resistant shoes for specific industries:

Manufacturing: In manufacturing facilities, oil and water are often present on the floor, making slip-resistant shoes a must-have. Look for shoes with a high-traction sole and a slip-resistant rating of at least 0.5. Brands like Dr. Martens and Timberland offer excellent options for manufacturing workers.

Construction: Construction sites are notorious for slippery surfaces, and oil water slip-resistant shoes are a vital part of a worker’s personal protective equipment (PPE). Choose shoes with a rugged outsole and a deep lug tread pattern to provide maximum traction. Thorogood and other brands offer high-quality options for construction workers.

Food Processing: In food processing facilities, oil and water are often present on the floor, and slip-resistant shoes are essential to prevent accidents. Look for shoes with a slip-resistant rating of at least 0.7 and a comfortable, breathable design. Brands like New Balance and Skechers offer excellent options for food processing workers.

Healthcare: In healthcare facilities, slip-resistant shoes are crucial to prevent accidents and injuries. Choose shoes with a slip-resistant rating of at least 0.5 and a comfortable, easy-to-clean design. Brands like Dansko and Clarks offer excellent options for healthcare workers.

When selecting oil water slip-resistant shoes for a specific industry, consider the unique challenges and requirements of the job. Look for shoes that meet or exceed industry standards, and choose a reputable brand that offers high-quality, certified footwear. By investing in the right oil water slip-resistant shoes, workers can reduce the risk of accidents and injuries, and create a safer, more productive work environment.

Remember, oil water slip-resistant shoes are not a one-size-fits-all solution. Different industries require different types of shoes, and it’s essential to choose the right shoes for the job. By following this guide, workers and employers can make informed decisions about oil water slip-resistant shoes and prioritize safety in hazardous work environments.

What to Look for in a Slip-Resistant Shoe Certification

When it comes to oil water slip-resistant shoes, certification is crucial. Certification ensures that the shoes meet specific standards for slip resistance, and provides workers and employers with confidence in the footwear’s ability to prevent accidents and injuries. But what do these certifications mean, and how do they impact the safety of workers?

ASTM Certification: The American Society for Testing and Materials (ASTM) is a leading organization for developing and publishing technical standards. ASTM certification for oil water slip-resistant shoes ensures that the footwear meets specific standards for slip resistance, including the ASTM F2913-19 standard. This standard tests the shoes’ ability to provide traction on oily and wet surfaces, and ensures that the shoes meet minimum requirements for slip resistance.

EN Certification: The European Union’s (EU) EN certification is another important standard for oil water slip-resistant shoes. EN certification ensures that the footwear meets EU standards for personal protective equipment (PPE), including slip resistance. The EN 20345:2011 standard is a common certification for oil water slip-resistant shoes, and ensures that the footwear provides a high level of protection against slips, trips, and falls.

Other Certifications: In addition to ASTM and EN certifications, there are other certifications that oil water slip-resistant shoes may carry. These include certifications from organizations such as the International Organization for Standardization (ISO) and the Canadian Standards Association (CSA). These certifications provide additional assurance that the footwear meets specific standards for slip resistance and safety.

When selecting oil water slip-resistant shoes, it’s essential to look for certifications from reputable organizations such as ASTM and EN. These certifications provide assurance that the footwear meets specific standards for slip resistance, and provides workers and employers with confidence in the footwear’s ability to prevent accidents and injuries. By choosing certified oil water slip-resistant shoes, workers can reduce the risk of slips, trips, and falls, and create a safer, more productive work environment.

Remember, oil water slip-resistant shoes are not a one-size-fits-all solution. Different industries and occupations require different types of shoes, and it’s essential to choose shoes that meet specific certifications and standards. By understanding the different certifications and standards for oil water slip-resistant shoes, workers and employers can make informed decisions about footwear and prioritize safety in hazardous work environments.

Conclusion: Prioritizing Safety with Oil and Water Slip-Resistant Shoes

In hazardous work environments, oil water slip-resistant shoes are a critical component of personal protective equipment (PPE). By understanding the importance of slip-resistant shoes, selecting the right shoes for the job, and prioritizing certification standards, workers and employers can reduce the risk of accidents and injuries. Oil water slip-resistant shoes are not just a necessity, but a vital investment in the safety and well-being of workers.

By choosing high-quality, certified oil water slip-resistant shoes, workers can enjoy a safer, more productive work environment. Whether in manufacturing, construction, food processing, or healthcare, oil water slip-resistant shoes provide a critical layer of protection against slips, trips, and falls. By prioritizing safety with oil water slip-resistant shoes, workers and employers can create a culture of safety and responsibility in the workplace.

Remember, oil water slip-resistant shoes are not a one-time investment, but a long-term commitment to safety. By staying informed about the latest developments in slip-resistant technology, certification standards, and industry-specific requirements, workers and employers can stay ahead of the curve and prioritize safety in hazardous work environments. Make the smart choice and invest in oil water slip-resistant shoes today – the safety of your workers depends on it.