Why Non-Slip Work Boots Matter: The Risks of Slipping on the Job

In the workplace, slips, trips, and falls are a major concern, resulting in injuries, fatalities, and significant financial losses. According to the Occupational Safety and Health Administration (OSHA), slips, trips, and falls account for 25% of all reported injuries in the workplace. In many cases, these accidents can be prevented by wearing the right footwear, specifically mens work boots non slip. Non-slip work boots are designed to provide traction and stability on various surfaces, reducing the risk of slipping and falling. The importance of non-slip work boots cannot be overstated, as they can mean the difference between a safe working environment and a hazardous one. In industries such as construction, manufacturing, and oil rig work, the risks of slipping and falling are even higher due to the presence of hazardous materials, uneven terrain, and inclement weather. By wearing mens work boots non slip, workers can significantly reduce their risk of injury and ensure a safe working environment.

What Makes a Good Non-Slip Work Boot: Key Features to Look For

When it comes to selecting the right mens work boots non slip for your job, there are several key features to look for to ensure optimal slip resistance and performance. One of the most critical components is the outsole material, which should be made of a durable, slip-resistant compound such as rubber or polyurethane. The tread pattern is also essential, as it provides traction and grip on various surfaces. Look for boots with deep treads and lugs that are specifically designed to channel water and debris away from the foot. Ankle support is another vital feature, as it helps to prevent twists and sprains. A good non-slip work boot should also have a sturdy, comfortable upper made of materials such as leather or synthetic fabrics. Additionally, consider the boot’s weight, flexibility, and breathability, as these factors can impact comfort and performance. By understanding the key features of non-slip work boots, you can make an informed decision when selecting the right pair for your job.

How to Choose the Right Non-Slip Work Boot for Your Job

Selecting the right mens work boots non slip for your job can be a daunting task, especially with the numerous options available in the market. However, by considering a few key factors, you can make an informed decision that ensures your safety and comfort on the job. First, consider the terrain you’ll be working on. If you’ll be working on slippery surfaces, such as oil rigs or construction sites, look for boots with aggressive tread patterns and deep lugs to provide maximum traction. If you’ll be working in wet or oily conditions, consider boots with waterproof membranes and slip-resistant outsoles. Weather is another crucial factor to consider. If you’ll be working in extreme temperatures, look for boots with insulation and breathable materials to keep your feet warm and dry. Finally, consider the specific requirements of your job. If you’ll be working at heights, look for boots with ankle support and slip-resistant soles. By taking these factors into account, you can choose the right mens work boots non slip for your job and ensure a safe and comfortable working environment.

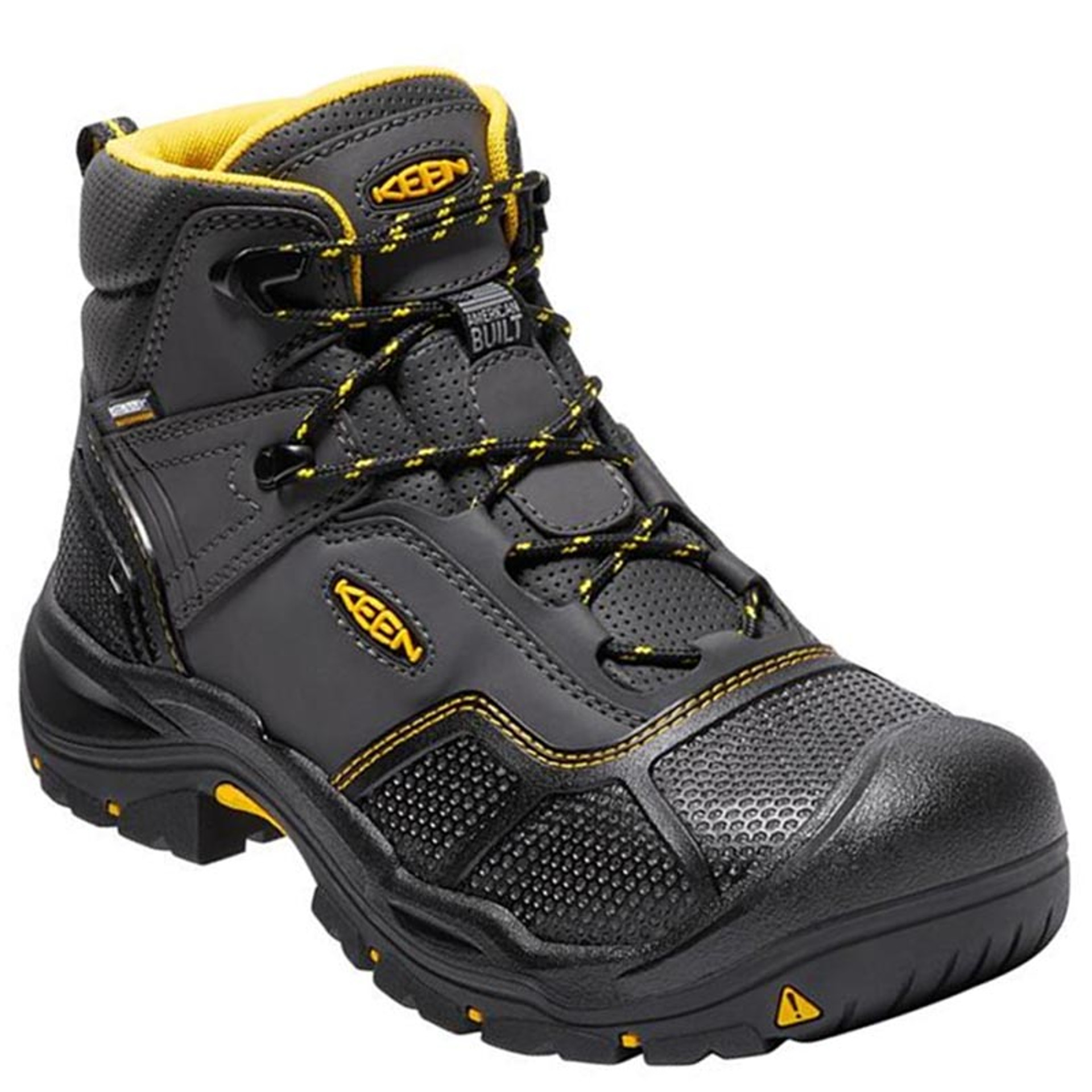

Top Non-Slip Work Boots for Men: Product Reviews and Comparisons

When it comes to selecting the best mens work boots non slip for your job, there are numerous options available in the market. To help you make an informed decision, we’ve reviewed and compared top-rated non-slip work boots for men from leading brands. Here are our top picks:

Topping our list is the Timberland PRO Boondock Work Boot, which features a rugged outsole with deep lugs for maximum traction and a comfortable, breathable upper. The Dr. Martens Ironbridge Work Boot is another top contender, with its air-cushioned sole and slip-resistant outsole making it ideal for workers who need to be on their feet all day. For those working in extreme conditions, the Thorogood American Made Work Boot is a great option, with its waterproof membrane and insulated upper keeping feet warm and dry.

Other notable mentions include the Carhartt CMF6371 Work Boot, which features a rugged, slip-resistant outsole and a comfortable, breathable upper, and the Dickies Work Boot, which offers a durable, slip-resistant outsole and a comfortable, adjustable fit. When choosing the best mens work boots non slip for your job, consider factors such as terrain, weather, and job requirements, and look for boots with features such as slip-resistant outsoles, breathable uppers, and comfortable, adjustable fits.

The Science Behind Non-Slip Technology: How It Works

Non-slip technology is a critical component of mens work boots non slip, and understanding how it works can help workers make informed decisions when selecting the right boots for their job. At its core, non-slip technology is designed to provide traction and prevent slipping on various surfaces. This is achieved through a combination of materials, designs, and features that work together to create a slip-resistant sole.

One of the key factors in non-slip technology is the outsole material. Rubber and polyurethane are common materials used in non-slip work boots, as they provide excellent grip and traction on various surfaces. The tread pattern is also crucial, as it helps to channel water and debris away from the sole, reducing the risk of slipping. Deep lugs and aggressive tread patterns are often used in mens work boots non slip to provide maximum traction on slippery surfaces.

In addition to outsole materials and tread patterns, other features such as ankle support and upper materials also play a role in non-slip technology. Ankle support helps to prevent twisting and rolling of the ankle, reducing the risk of slipping and falling. Upper materials such as breathable mesh and waterproof membranes help to keep feet dry and comfortable, reducing the risk of slipping due to wet or sweaty feet.

The science behind non-slip technology is based on the principles of friction and traction. When a boot comes into contact with a surface, the outsole material and tread pattern work together to create friction, which prevents slipping. The level of friction required to prevent slipping depends on the surface and the conditions, which is why mens work boots non slip are designed to provide varying levels of traction and slip resistance.

By understanding the science behind non-slip technology, workers can make informed decisions when selecting the right mens work boots non slip for their job. Whether working on slippery surfaces, in wet or oily conditions, or in extreme temperatures, non-slip work boots are essential for preventing slips, trips, and falls, and ensuring a safe and comfortable working environment.

Slip-Resistant vs. Non-Slip: What’s the Difference?

When it comes to mens work boots non slip, understanding the difference between slip-resistant and non-slip work boots is crucial. While both types of boots are designed to provide traction and prevent slipping, they differ in their level of slip resistance and the conditions in which they are suitable.

Slip-resistant work boots are designed to provide a moderate level of traction on surfaces that are slightly slippery or oily. They are often used in occupations such as manufacturing, warehousing, and food processing, where the risk of slipping is moderate. Slip-resistant boots typically feature a rubber or polyurethane outsole with a moderate tread pattern, which provides a good balance between traction and durability.

Non-slip work boots, on the other hand, are designed to provide a high level of traction on extremely slippery surfaces, such as those found in construction, oil rig work, or heavy industry. They feature a more aggressive tread pattern and a specialized outsole material that is designed to grip surfaces tightly, even in wet or oily conditions. Non-slip boots are often used in occupations where the risk of slipping is high, and the consequences of a fall can be severe.

Choosing the right type of mens work boots non slip for your job is essential. Slip-resistant boots may be sufficient for occupations with moderate slip hazards, but non-slip boots are necessary for occupations with high slip hazards. Workers should consider the terrain, weather, and job requirements when selecting the right type of boot, and should always prioritize safety and comfort.

In summary, while both slip-resistant and non-slip work boots are designed to prevent slipping, they differ in their level of slip resistance and the conditions in which they are suitable. By understanding the difference between these two types of boots, workers can make informed decisions when selecting the right mens work boots non slip for their job.

Breaking In Your Non-Slip Work Boots: Tips for Comfort and Performance

When it comes to mens work boots non slip, breaking in a new pair can be a daunting task. However, with the right techniques and strategies, workers can ensure a comfortable and high-performing fit. Breaking in non-slip work boots is essential to prevent discomfort, blisters, and fatigue, and to ensure optimal performance on the job.

One of the most effective ways to break in non-slip work boots is to condition the leather. This can be done by applying a leather conditioner or oil to the boots, paying special attention to the areas that come into contact with the foot. Conditioning the leather helps to soften and flex the material, making it more comfortable and pliable.

Another key step in breaking in non-slip work boots is to stretch the material. This can be done by wearing the boots for short periods of time and gradually increasing the duration. Workers can also try stretching the boots by hand, using a boot stretcher, or by applying heat to the material. Stretching the material helps to mold the boots to the foot, providing a comfortable and customized fit.

Adjusting to the fit of non-slip work boots is also crucial. Workers should try on the boots with the same type of socks they plan to wear on the job, and should walk around to ensure a comfortable fit. Adjusting the laces, tongue, and ankle support can also help to customize the fit and prevent discomfort.

Additionally, workers should consider the type of non-slip work boots they are wearing. For example, boots with a more aggressive tread pattern may require a longer break-in period, while boots with a more flexible outsole may be more comfortable right out of the box.

By following these tips and strategies, workers can ensure a comfortable and high-performing fit with their mens work boots non slip. Whether working in construction, manufacturing, or oil rig work, a well-broken-in pair of non-slip work boots is essential for optimal performance and safety on the job.

Maintenance and Care: Extending the Life of Your Non-Slip Work Boots

Proper maintenance and care are essential to extend the life of mens work boots non slip and maintain their slip-resistant properties. By following a few simple tips, workers can ensure their non-slip work boots remain in top condition, providing optimal performance and safety on the job.

Cleaning is a crucial step in maintaining non-slip work boots. Workers should regularly remove dirt, debris, and oils from the boots using a soft-bristled brush and mild soap. Avoid using harsh chemicals or abrasive materials that can damage the outsole or upper material.

Conditioning is also vital to extend the life of non-slip work boots. Workers should apply a leather conditioner or oil to the boots, paying special attention to the areas that come into contact with the foot. Conditioning helps to moisturize the leather, preventing cracks and dryness that can compromise the boot’s slip resistance.

Storing non-slip work boots properly is also important. Workers should store their boots in a cool, dry place, away from direct sunlight and heat sources. Avoid stacking boots on top of each other, as this can cause damage to the outsole or upper material.

In addition to cleaning, conditioning, and storing, workers should also inspect their non-slip work boots regularly for signs of wear and tear. Check the outsole for excessive wear, the upper material for cracks or tears, and the laces and hardware for damage or corrosion. Addressing these issues promptly can help prevent more serious problems from developing.

By following these simple maintenance and care tips, workers can extend the life of their mens work boots non slip, ensuring optimal performance and safety on the job. Whether working in construction, manufacturing, or oil rig work, well-maintained non-slip work boots are essential for success.