Decoding Protective Footwear Specifications

The ASTM F2413 standard serves as a cornerstone for protective footwear. It establishes crucial performance requirements for work boots. These requirements apply across various industries. The standard’s primary goal is to ensure worker safety. Choosing the right work boots is vital. This selection must align with the specific hazards of the job. This article will explore the evolution of this standard. There are different versions of this standard. These revisions reflect advancements in safety technology. It’s important to be aware of the various versions. This awareness helps in making informed decisions.

Understanding the purpose of ASTM F2413 is the first step. The standard aims to protect workers’ feet from various workplace hazards. These hazards include impact, compression, and electrical risks. The standard specifies testing methods. These methods evaluate a boot’s protective capability. This evaluation is to ensure that footwear meets the requirements. The standard is revised periodically. These revisions incorporate new research and industry changes. This focus helps to keep the standard up to date and effective. This includes significant differences between the astm f2413-11 vs astm f2413-18 versions. The existence of multiple versions underscores the need for vigilance. It also highlights the importance of selecting footwear that meets the latest standards.

Therefore, this comparison of astm f2413-11 vs astm f2413-18 is essential for understanding these changes. It’s key to selecting protective footwear that provides the best safety possible. This exploration will shed light on the differences. It will also address practical implications for workers. This journey into understanding the ASTM F2413 standard is beneficial for all stakeholders.

ASTM F2413-11 Versus F2413-18: Key Differences in Safety Footwear Standards

The shift from ASTM F2413-11 to ASTM F2413-18 represents a significant evolution in safety footwear standards. These revisions were implemented to enhance worker protection. The update reflects advancements in materials and testing methodologies. One of the key changes involves the way footwear is assessed for impact resistance. The 2018 standard introduced more stringent testing criteria. These changes directly impact the level of protection offered. It’s essential to understand that while both standards aim to protect, the newer version offers a higher level of safety. This means footwear that meets the ASTM F2413-18 requirements provides more robust protection against workplace hazards.

The modifications between ASTM F2413-11 vs ASTM F2413-18 encompass several areas. Updates include changes to the testing apparatus. There are also alterations to the manner in which the tests are executed. These adjustments were designed to provide more realistic simulations. The result is a more accurate assessment of a boot’s protective capabilities. These changes are not just about numbers; they are about ensuring better safety for wearers. The goal of the 2018 revision was to improve real-world protection. Therefore, understanding the differences between the two standards is crucial for selecting appropriate safety footwear. The updated standard addresses some of the shortcomings and vulnerabilities identified under the previous one. It is important for employers and workers to be aware of these differences.

The advancements in the ASTM F2413-18 standard cover material science. It also impacts test methods for compression resistance. This means that footwear tested under the 2018 standards should hold up better. It should perform better in harsh conditions. These alterations reflect the ongoing efforts to enhance safety in the workplace. The difference between ASTM F2413-11 vs ASTM F2413-18 boils down to better performance. The revised tests are more precise. This helps manufacturers create a higher caliber of protective footwear. This ultimately leads to greater worker protection. When considering which safety footwear to purchase, prioritize those certified with ASTM F2413-18. It indicates a commitment to the most current standards in safety. The new requirements improve safety and also give more confidence in the footwear.

Impact Resistance: How the Standards Differ in Impact Testing

The assessment of impact resistance is a crucial component of both the ASTM F2413-11 and ASTM F2413-18 standards, although the latter introduces key updates. Both standards aim to measure how well safety footwear can protect the foot from impacts. However, the methodology and specifics differ. The ASTM F2413-11 standard uses a specific weight dropped from a certain height onto the toe area. The 2018 revision of the standard, ASTM F2413-18, maintains the core concept but refines the criteria. This includes changes in the impact force and the resulting clearance requirements within the footwear. These modifications mean that footwear certified under the updated standard might offer a higher degree of impact protection, due to a refined testing process that potentially accounts for more realistic scenarios. The standards specify the impact energy delivered in Joules and the minimum clearance that must remain under the steel toe cap or toe protective material after impact. These values determine if the footwear passes or fails the impact testing requirements.

When comparing astm f2413-11 vs astm f2413-18 specifically regarding impact testing, the updates within the latter reflect lessons learned from field experience and technological advancements. These changes are not arbitrary. They aim to ensure that the footwear provides a reliable protection in real-world situations. The revisions to impact resistance testing in ASTM F2413-18 generally results in a more robust standard. The updated requirements challenge manufacturers to enhance the design and materials used in safety toe boots. This directly translates to potentially safer footwear for workers who depend on such protection daily. The F2413-18 standard introduces a refined approach in the impact testing, with changes designed to raise the bar for safety and performance. The aim is for increased reliability of protective footwear in the field. The newer tests are more relevant to the types of impacts that workers are likely to encounter in various work environments.

The practical implications of these alterations in impact resistance standards are significant. Footwear that meets the requirements of ASTM F2413-18 has likely gone through more stringent testing than those that conform only to F2413-11. The user benefits from potentially improved protection. This is especially true in settings where impact hazards are prevalent. It’s important to recognize that not all safety boots that meet the updated ASTM F2413-18 standard will perform identically, as compliance only means that the boot meets minimum standards. However, the updated test methods provide more confidence that the product will offer the protection it is intended for. Thus, for professionals whose work exposes them to potential impact injuries, choosing footwear based on the latest standard is advisable. The revised standard reflects an ongoing effort to provide better and more effective safety equipment.

Compression Testing: A Comparative Look Between F2413-11 and F2413-18

Compression testing evaluates a safety footwear’s ability to withstand static compressive forces. Both the ASTM F2413-11 and the newer ASTM F2413-18 standards include this crucial assessment. It is essential to understand how the two versions differ. The tests assess how much pressure the footwear can endure before it deforms or fails. This is crucial to protect the wearer’s feet from heavy objects or machinery that could exert significant static pressure. Materials like steel, aluminum, and composites are often used in the construction of safety shoes for compression resistance. These materials are designed to withstand such forces and protect the wearer.

The core principle of compression testing remains consistent between both versions. However, the ASTM F2413-18 introduces some crucial nuances. The testing criteria or requirements were refined to provide a more accurate measure of a boot’s protective capabilities. The focus was on better simulating real-world conditions. These changes ensure that the tested boots offer better protection against compression injuries. This revision reflects the ongoing effort to improve safety standards. The differences between the astm f2413-11 vs astm f2413-18 standards are about increasing worker safety. It ensures that the chosen footwear truly lives up to its protective claims. This makes understanding these refinements important for both manufacturers and users.

The ASTM F2413-18 version seeks to ensure consistency and better results. This translates into safer footwear in the workplace. The newer standard updates the testing protocols to address deficiencies. The protocols focus on improving material durability. It makes use of updated materials, which offer superior resistance. The revisions ensure a more consistent testing process. This leads to better protection against workplace hazards. The ASTM F2413-18 offers advancements in safety footwear technology. The standards also offer the most reliable results possible. Selecting safety footwear should now consider this improvement. The slight changes in the methodology are still very important to overall safety.

How to Select Safety Boots that Meet the Latest ASTM Standards

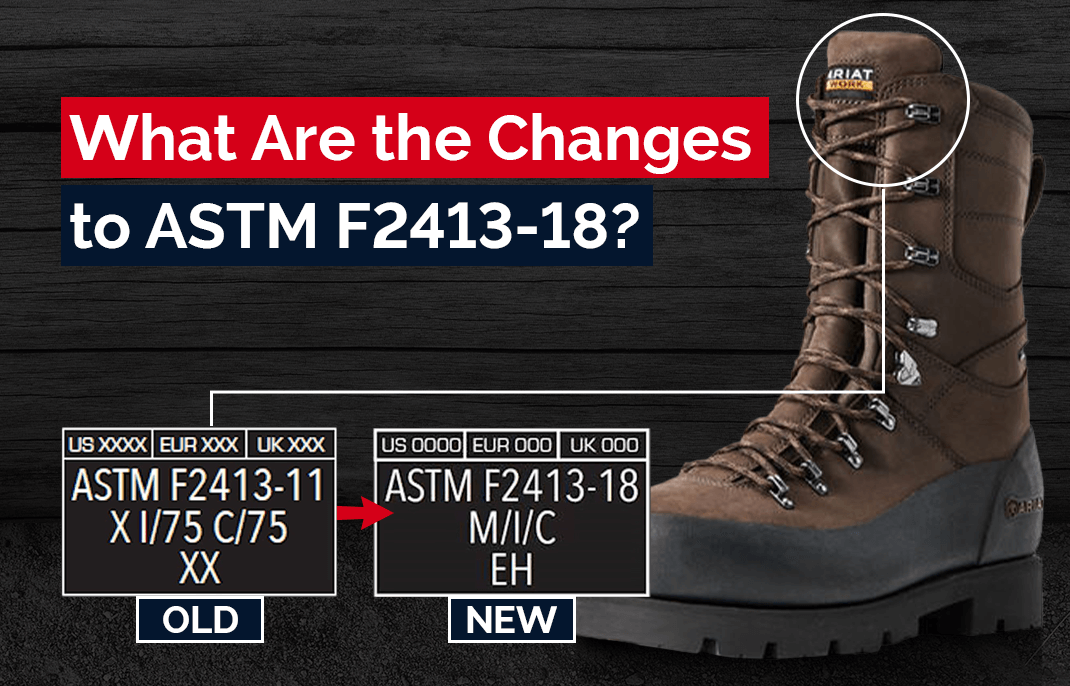

Selecting safety boots that comply with the current ASTM F2413-18 standard is crucial for workplace safety. Begin by checking the boot’s labeling. The label should clearly state that it meets the ASTM F2413-18 standard. Look for markings that indicate the specific protection features, such as impact (I) and compression (C) resistance. Understanding these markings is essential to ensure the boots match your job’s hazards. Verify that the boots meet or exceed the specific needs of your work environment, since requirements vary between industries. Some common brands like Caterpillar, Timberland PRO, and Wolverine offer models that meet the updated standards. They often provide detailed product specifications online and in their catalogs. When browsing through these brands or others, look for explicit mention of ASTM F2413-18 compliance in their product descriptions.

It’s important to go beyond just brand recognition. Focus on the specific safety features advertised. For example, if your work involves a high risk of falling objects, prioritize boots with high impact resistance ratings. If you often handle heavy materials, compression ratings become more critical. Remember that the updated standard, ASTM F2413-18, introduced some differences when compared to ASTM F2413-11, so older models may not offer the same protection level. Thus, comparing the standards, `astm f2413-11 vs astm f2413-18`, ensures you are equipped with the latest safety innovations and guidelines. Consulting a safety professional can also offer useful guidance on the exact type of boots suitable for your role. The goal should be to select footwear that not only meets but exceeds the necessary protection benchmarks.

Finally, always ensure that the boots fit correctly. A poorly fitted boot can compromise safety and comfort. Try on boots with the type of socks you typically wear for work. Walk around to ensure there is no slipping or discomfort. Consider factors like the boot’s material, the sole’s grip, and overall construction. All these components have an impact on daily comfort and safety. A proper fit allows for maximum protection and prevents foot injuries. Don’t hesitate to invest in high-quality safety footwear. Doing so provides greater long-term value as well as ensuring you stay protected and productive at work while complying with `astm f2413-11 vs astm f2413-18` requirements.

What Do Safety Footwear Labels Tell You About ASTM Requirements?

Safety footwear labels are critical for understanding a boot’s protective capabilities. These labels provide a shorthand for the complex requirements outlined in standards like ASTM F2413. The codes and markings are not arbitrary. They directly correspond to specific performance criteria. For instance, a label will indicate whether a boot meets the impact (I) and compression (C) resistance standards. These are crucial for protection against workplace hazards. Understanding these markings ensures you choose footwear appropriate for your specific needs. The goal is to ensure the right protection. It is also important for compliance with workplace safety regulations.

Decoding labels requires familiarity with the ASTM F2413 standard. A label might include “I/75” or “C/75”. These indicate the boot is rated to withstand a 75-foot-pound impact and 2500 pounds of compression. These ratings are consistent within the same standard year. The codes also highlight specific protections like metatarsal (Mt) or electrical hazard (EH) resistance. Each standard, including the distinction between

Safety footwear labels offer more than just compliance confirmation. They give essential information for users. Markings serve as a quick reference. These are for workers to understand protection features. When comparing boots, knowing these labels can be crucial for the correct choice. The

Practical Implication of Standard Revisions on Footwear Choices

The shift from astm f2413-11 vs astm f2413-18 significantly impacts those who rely on safety footwear daily. These revisions are not merely technical adjustments. They represent a commitment to enhanced worker protection. The updated standards mean that footwear now provides a higher level of defense. This protects against workplace hazards. The changes in impact resistance, for instance, offer better safeguarding against falling objects. Enhanced compression testing ensures greater protection against heavy loads. These advancements provide a greater peace of mind for workers in demanding environments. The revisions in testing protocols ultimately translate to tangible safety improvements on the job.

The implications of astm f2413-11 vs astm f2413-18 are far-reaching. The updated standard mandates a more rigorous testing process. This ensures that all certified footwear meets a higher standard of safety. The shift may require companies to re-evaluate their safety footwear programs. They must ensure compliance with the latest regulations. For individuals, it means increased assurance in their protective gear. It also means that the choices available are more closely aligned with real-world safety needs. It is vital for employers and employees to understand the differences. It is important to ensure they are selecting and using the correct safety footwear.

In conclusion, the differences between astm f2413-11 vs astm f2413-18 are crucial to understand. They directly influence the protective capabilities of work boots. The revisions have been made to address new challenges and to enhance existing safety protocols. These changes ensure improved protection. The changes also reflect a dedication to reducing workplace injuries. The transition to updated standards represents an important step. This step creates a safer work environment for everyone involved. Understanding these changes is key for all stakeholders. This includes manufacturers, employers, and workers alike. It will contribute to a safer and more secure working environment.

The Future of Safety Footwear Standards and Why They Matter

The evolution of safety footwear standards is a continuous process. It responds to new workplace challenges and technological advancements. Keeping up-to-date with regulations like ASTM F2413 is crucial. This ensures that protective footwear meets the latest safety requirements. Future revisions to standards are anticipated. They will likely incorporate new materials and testing methodologies. These changes aim to enhance worker protection further. The ongoing development of safety footwear reflects a proactive approach to workplace safety. It seeks to minimize risks and injuries through improved technology and standards. Understanding the differences between standards such as astm f2413-11 vs astm f2413-18 is essential for stakeholders.

The significance of these standards extends beyond compliance. They drive innovation in footwear design and manufacturing. As research and technology advance, so do the possibilities for enhanced safety features. We can expect to see developments in areas such as impact absorption. Also, improvements in materials will make footwear more durable and comfortable. These changes will benefit workers by providing better protection. It will also improve their overall experience while wearing protective boots. The continuous pursuit of improvement is central to the process. The evolution in standards will also ensure relevance and effectiveness of protective footwear.

Looking ahead, the future of safety footwear will likely be shaped by two main factors. The first is an increased emphasis on preventative measures. It aims to anticipate and mitigate workplace hazards more effectively. The second is the integration of smart technologies. This includes sensors and monitoring systems. These will potentially provide real-time data on footwear performance. They will also be useful in detecting potential problems. By embracing innovation and maintaining a strong focus on safety, industries can ensure that workers are well-protected. This is done using the most advanced, and reliable safety footwear available. Understanding the progress made from astm f2413-11 vs astm f2413-18 helps inform that need for constant evolution.