What’s Behind the Changes in ASTM F2413?

In various industries, safety standards play a crucial role in ensuring the well-being of workers. One such standard is ASTM F2413, which specifically focuses on foot protection. The importance of ASTM F2413 lies in its ability to provide a framework for manufacturers, suppliers, and employers to ensure that safety footwear meets the required performance and testing criteria. As industries evolve and new hazards emerge, it becomes essential to update safety standards to address these changes. This is precisely why ASTM F2413 has undergone revisions, with the latest version being ASTM F2413-18. Understanding the reasons behind these changes is vital for industries to adapt and maintain a safe working environment. The comparison between ASTM F2413-05 vs ASTM F2413-18 is crucial in identifying the key differences and their implications on foot protection. In this article, we will delve into the differences between these two versions, exploring the implications of these changes and what they mean for manufacturers, suppliers, and employers.

Unpacking the Key Differences Between ASTM F2413-05 and ASTM F2413-18

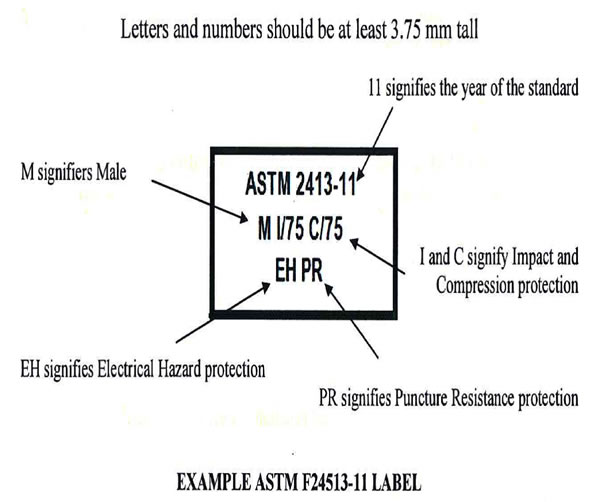

The evolution of safety standards is a continuous process, and ASTM F2413 is no exception. The 2005 and 2018 versions of the standard have distinct differences, which are crucial to understand for industries that rely on safety footwear. One of the primary differences between ASTM F2413-05 and ASTM F2413-18 is the updated testing methods and performance requirements. The 2018 version introduces more stringent testing protocols to ensure that safety footwear meets the required standards. Additionally, the updated standard includes revised labeling guidelines, which provide clearer information to users about the protection offered by the footwear. Another significant difference is the inclusion of new hazard categories in ASTM F2413-18, which address emerging risks in various industries. By understanding these key differences, industries can make informed decisions about the safety footwear they use and ensure compliance with the latest standard. The comparison between ASTM F2413-05 vs ASTM F2413-18 is essential in identifying the key differences and their implications on foot protection.

How to Choose the Right Safety Footwear for Your Workplace

Selecting the appropriate safety footwear is crucial for ensuring the safety and well-being of workers in various industries. With the evolution of safety standards, it’s essential to understand the differences between ASTM F2413-05 and ASTM F2413-18 to make informed decisions. When choosing safety footwear, consider the specific hazards present in your workplace and the level of protection required. For example, if you work in a construction site, you may need footwear that meets the ASTM F2413-18 standard for impact and compression resistance. On the other hand, if you work in a manufacturing environment, you may require footwear that meets the ASTM F2413-05 standard for electrical hazard protection. It’s also important to consider the comfort and durability of the footwear, as well as any additional features that may be required, such as slip resistance or waterproofing. By understanding the differences between ASTM F2413-05 vs ASTM F2413-18, you can ensure that your workers are protected from foot injuries and that your organization is compliant with the latest safety standards.

A Closer Look at the Impact of ASTM F2413-18 on Foot Protection

The updated ASTM F2413-18 standard has introduced significant changes to the testing methods, performance requirements, and labeling guidelines for safety footwear. One of the key changes is the revised testing protocol for impact and compression resistance, which provides a more accurate assessment of a footwear’s ability to protect against foot injuries. Additionally, the updated standard includes new requirements for electrical hazard protection, which ensures that safety footwear meets the necessary standards for industries where electrical hazards are present. The labeling guidelines have also been revised to provide clearer information to users about the protection offered by the footwear. For example, the new standard requires that footwear be labeled with specific markings indicating the level of protection against hazards such as impact, compression, and electrical shock. By understanding the specific changes introduced in ASTM F2413-18, industries can ensure that their safety footwear meets the latest standards and provides adequate protection for their workers. When comparing ASTM F2413-05 vs ASTM F2413-18, it’s clear that the updated standard provides a more comprehensive approach to foot protection, and its adoption is crucial for industries that prioritize worker safety.

What Do the Changes Mean for Manufacturers and Suppliers?

The updated ASTM F2413-18 standard has significant implications for manufacturers and suppliers of safety footwear. With the revised testing methods, performance requirements, and labeling guidelines, manufacturers must ensure that their products comply with the new standard. This may require investments in new testing equipment, updated manufacturing processes, and revised labeling and marketing materials. Non-compliance with the standard can result in serious consequences, including product recalls, fines, and damage to reputation. On the other hand, compliance with ASTM F2413-18 can provide a competitive advantage, as manufacturers can demonstrate their commitment to providing high-quality, safe products that meet the latest industry standards. When comparing ASTM F2413-05 vs ASTM F2413-18, manufacturers must consider the benefits of adopting the updated standard, including improved product performance, enhanced customer trust, and reduced liability. By understanding the implications of the updated standard, manufacturers and suppliers can ensure a smooth transition to ASTM F2413-18 and maintain their position in the market.

Real-World Applications of ASTM F2413-18 in Various Industries

The updated ASTM F2413-18 standard is being implemented in various industries, including construction, manufacturing, and oil and gas, where foot protection is crucial. In the construction industry, for example, ASTM F2413-18 is being used to ensure that safety footwear meets the necessary standards for protection against hazards such as falling objects, electrical shock, and slips, trips, and falls. In manufacturing, the standard is being applied to ensure that workers are protected from hazards such as heavy machinery, sharp objects, and hot surfaces. In the oil and gas industry, ASTM F2413-18 is being used to protect workers from hazards such as explosions, fires, and chemical spills. The adoption of ASTM F2413-18 in these industries has several benefits, including improved worker safety, reduced risk of injuries and fatalities, and increased compliance with regulatory requirements. When comparing ASTM F2413-05 vs ASTM F2413-18, it’s clear that the updated standard provides a more comprehensive approach to foot protection, and its adoption is crucial for industries that prioritize worker safety. By understanding the real-world applications of ASTM F2413-18, industries can ensure that they are providing the necessary protection for their workers and reducing the risk of accidents and injuries.

Ensuring Compliance with ASTM F2413-18: A Step-by-Step Guide

To ensure compliance with the updated ASTM F2413-18 standard, organizations must take a proactive approach to auditing, testing, and certification. Here are some steps to follow: First, conduct a thorough audit of your safety footwear products to identify any areas that may not meet the requirements of ASTM F2413-18. Next, update your testing protocols to ensure that they align with the new standard. This may involve investing in new testing equipment or partnering with a third-party testing laboratory. Once you have updated your testing protocols, certify your products to ensure that they meet the requirements of ASTM F2413-18. This may involve working with a certification body or obtaining self-certification. Finally, ensure that your labeling and marketing materials comply with the updated standard. By following these steps, organizations can ensure that their safety footwear products meet the requirements of ASTM F2413-18 and provide a safe working environment for their employees. When comparing ASTM F2413-05 vs ASTM F2413-18, it’s clear that the updated standard provides a more comprehensive approach to foot protection, and ensuring compliance is crucial for industries that prioritize worker safety.

The Future of Foot Protection: Trends and Innovations

The evolution of safety standards, as seen in the updates from ASTM F2413-05 to ASTM F2413-18, is a continuous process. As industries and workplaces continue to evolve, so too must the standards that govern them. In the future, we can expect to see even more innovative and effective approaches to foot protection. One trend that is likely to shape the future of foot protection is the increasing use of advanced materials and technologies, such as nanomaterials and 3D printing. These advancements have the potential to create even lighter, stronger, and more comfortable safety footwear. Another area of innovation is in the development of smart safety footwear, which can detect hazards and alert workers in real-time. Additionally, there may be updates to ASTM F2413-18 in the future, which could include further refinements to testing methods, performance requirements, and labeling guidelines. As the landscape of foot protection continues to evolve, it’s essential for industries and workplaces to stay ahead of the curve and adopt the latest standards and innovations. By doing so, they can ensure a safer and healthier work environment for their employees. When considering ASTM F2413-05 vs ASTM F2413-18, it’s clear that the updated standard provides a more comprehensive approach to foot protection, and staying informed about future developments will be crucial for industries that prioritize worker safety.